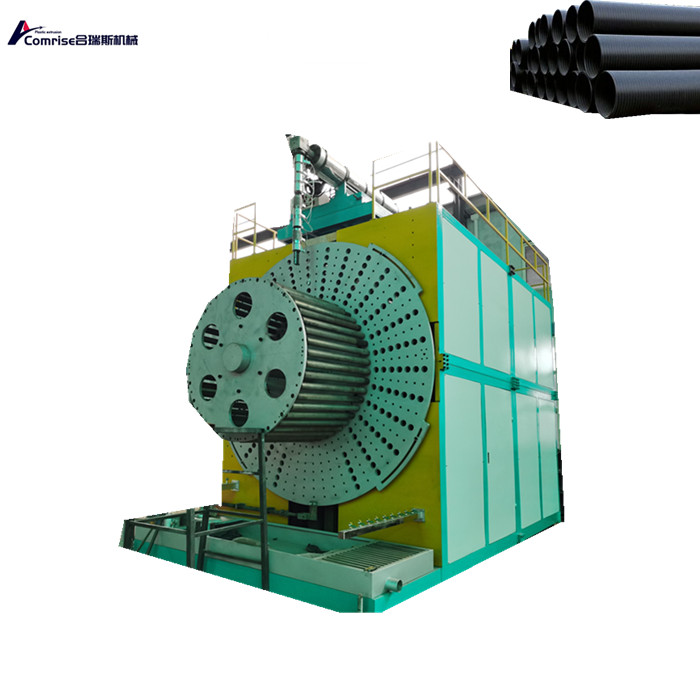

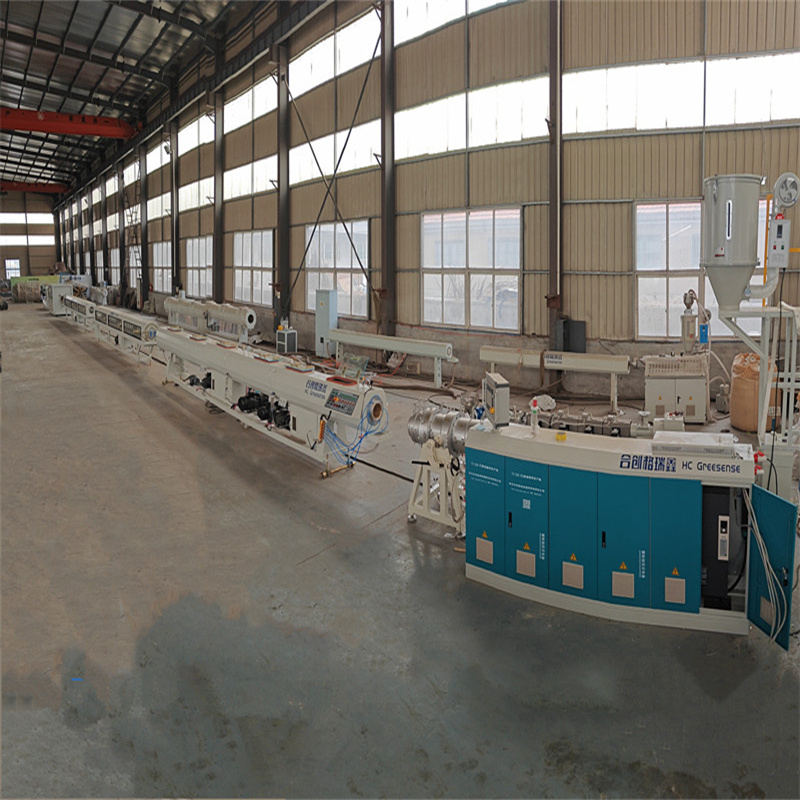

ஏபிஏ மூன்று அடுக்கு கோ எக்ஸ்ட்ரூஷன் எச்டிபிஇ குழாய் இயந்திரம்

விசாரணையை அனுப்பு

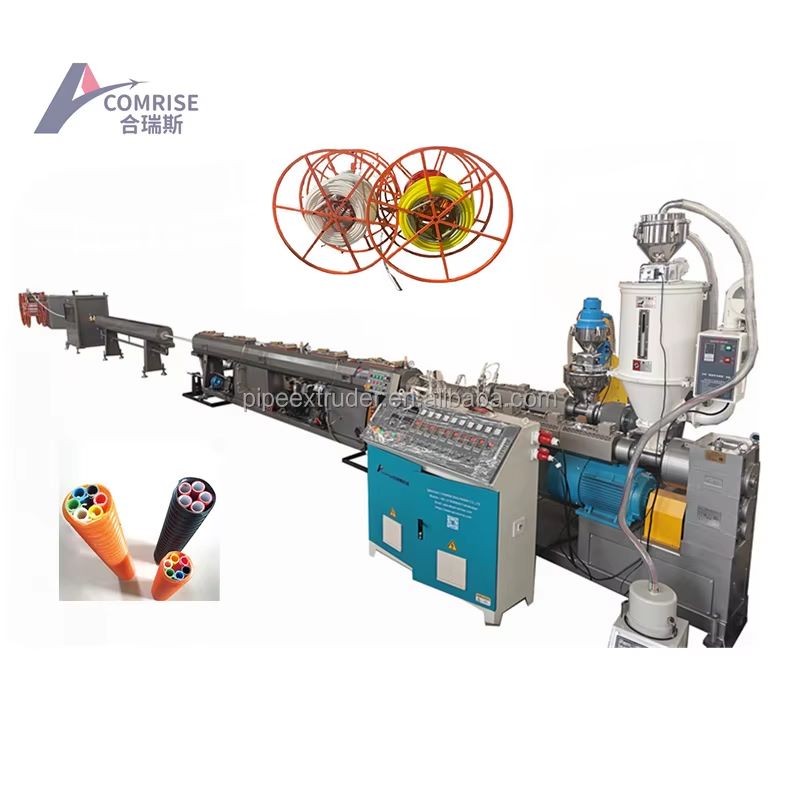

எஸ்.ஜே -75/33 ஒற்றை திருகு எக்ஸ்ட்ரூடர்

இந்த ஏபிஏ மூன்று அடுக்கு கோ எக்ஸ்ட்ரூஷன் எச்டிபிஇ குழாய் இயந்திர எக்ஸ்ட்ரூடர் பிபி/எச்டிபிஇ துகள்களை, கன்னி துகள்கள் அல்லது மறுசுழற்சி ஸ்கிராப்புகளை செயலாக்குவதற்காக சிறப்பாக வடிவமைக்கப்பட்டுள்ளது. வெவ்வேறு குழாய் அளவு மற்றும் தடிமன் அடிப்படையில் 45 கிலோவாட் டிரைவிங் மோட்டார் மூலம் எக்ஸ்ட்ரூடர் நிறுவப்பட்டுள்ளது.

எங்கள் திருகு HDPE-80/100 வேதியியல் பண்புகளின்படி குறிப்பாக ஆழமான துணிச்சலான வடிவமைப்பாகும். இது அதிக உறுதியான தன்மை, அதிக தாக்கம் மற்றும் நல்ல வளைக்கும் செயல்திறன், அதிக வெப்பநிலை எதிர்ப்பின் நன்மைகளைக் கொண்டுள்ளது. முதலியன.

சீனா டாப் மெஷின் தொழிற்சாலை

இணை விடுதலை எக்ஸ்ட்ரூடர்

எஸ்.ஜே -45/30 மிமீ ஒற்றை திருகு எக்ஸ்ட்ரூடர் [7.5/11 கிலோவாட்]

திருகு மற்றும் பீப்பாய் தொகுப்பு: 38Crmoal, LD: 30/1, இணை வெளியேற்ற கன்னி பொருளுக்கான சிறப்பு படிப்படியான வடிவமைப்பு.

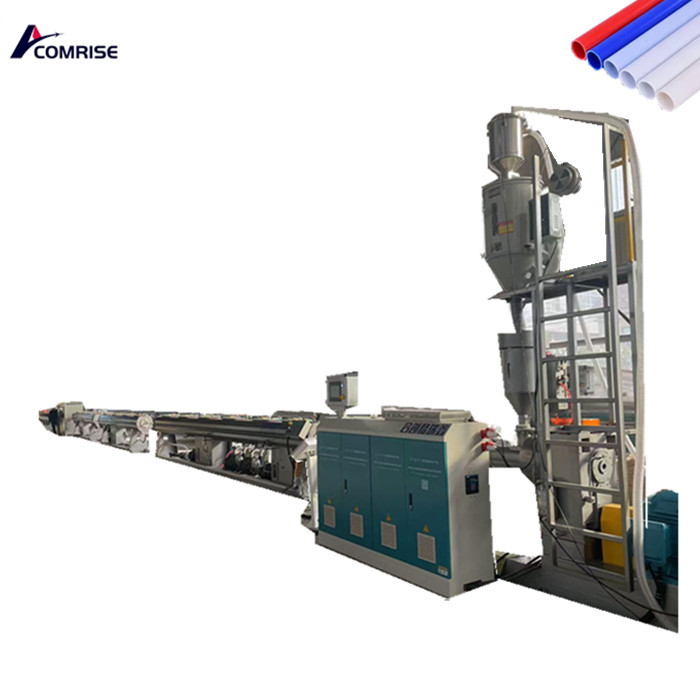

வெளியேற்ற அச்சு: அளவு 20-110 மிமீ

விட்டம்: φ20 மிமீ, φ25 மிமீ, φ32 மிமீ, φ40 மிமீ, φ50 மிமீ, φ63 மிமீ, φ75 மிமீ, φ90 மிமீ, φ110 மிமீ.

ஏபிஏ 3-அடுக்கு அச்சு/ ஏபி 2-அடுக்கு அச்சு

ஒரு 10% + B 80% + A 10%

இந்த ஏபிஏ மூன்று அடுக்கு கோ எக்ஸ்ட்ரூஷன் எச்டிபிஇ குழாய் இயந்திரத்தில், நாங்கள் ஏபிஏ 3-லேயர்களுக்கு தேர்வு தருகிறோம்.

ஏபிசி 3-அடுக்குகளுக்கு, விரிவான தீர்வுக்கு கூடுதல் ஒரு செட் இணை எக்ஸ்ட்ரூடர் இயந்திரத்தைச் சேர்க்கவும், எங்களை சுதந்திரமாக தொடர்பு கொள்ளவும்.

ஏபிஏ 3-அடுக்கு அச்சு/ ஏபி 2-அடுக்கு அச்சு

ஒரு 10% + B 80% + A 10%

இந்த இயந்திரத்தில், நாங்கள் ஏபிஏ 3-லேயர்களுக்கு தேர்வு தருகிறோம்.

ஏபிசி 3-அடுக்குகளுக்கு, விரிவான தீர்வுக்கு கூடுதல் ஒரு செட் இணை எக்ஸ்ட்ரூடர் இயந்திரத்தைச் சேர்க்கவும், எங்களை சுதந்திரமாக தொடர்பு கொள்ளவும்.

குளிரூட்டும் நீர் தொட்டியை வெற்றிடம் & தெளித்தல்

வெற்றிட குளிரூட்டும் நீர் தொட்டி இரண்டு அறை சுயாதீன வடிவமைப்பு ஆகும், இது மொத்த நீளம் 6000 மிமீ ஆகும், முதல் பிரிவு டர்போ வடிவமைப்பு. இது விரைவாக வெப்பநிலையை குளிர்விக்கும், மேலும் குழாயை வடிவமைக்கலாம். இரண்டாவது பிரிவு 4 மீ நீளமானது, இது குளிரூட்டும் விளைவை வலிமையாக்கலாம், குளிரூட்டும் நேரத்தை சுருக்கலாம்.

தெளிக்கும் குளிரூட்டும் நீர் தொட்டி 6 மீ நீளம் கொண்டது.

தெளிக்கும் தொட்டி தொட்டியின் உள்ளே நீர் தெளிப்பதற்காக 3 கிலோவாட் டிரைவிங் மோட்டார் மூலம் நிறுவப்பட்டுள்ளது.

குழாய் எதிர்காலத்தை குளிர்விக்க நாங்கள் அதைத் தயாரிக்கிறோம்

2-நகங்கள் இழுவை இயந்திரம்

ஏபிஏ மூன்று அடுக்கு கோ எக்ஸ்ட்ரூஷன் எச்டிபிஇ குழாய் இயந்திர இழுவை இயந்திர வடிவமைப்பு 3-கிராலர் வகை, அல்லது இது இரண்டு கம்பளிப்பூச்சி வகையாக இருக்கலாம்.

இது நிலையான வேகத்தில் குழாயை இழுக்க மாறி -அதிர்வெண் வேக ஒழுங்குமுறையைப் பயன்படுத்துகிறது.

வேக சரிசெய்தல் வரம்பு அகலமானது, இது நிலைத்தன்மையை உறுதிப்படுத்த முடியும்

உற்பத்தி செயல்முறை மற்றும் குழாயின் நேர்மை.

சிப் அல்லாத வெட்டு இயந்திரம்

ஏபிஏ மூன்று லேயர் கோ எக்ஸ்ட்ரூஷன் எச்டிபிஇ குழாய் இயந்திரம் தானியங்கி சிப் இல்லாத கட்டிங் மெஷின் ஒரு ஹைட்ராலிக் உணவு முறையைப் பயன்படுத்துகிறது

தொகுப்பு நீளத்திற்கு ஏற்ப குழாயை வெட்ட. கட்டிங் எண்ட் பூச்சு சுத்தமாகவும் மென்மையாகவும் இருக்கிறது,

சத்தம், தூசி மாசுபாடு அல்லது பொருள் கழிவு இல்லாமல்.

இப்போது ஒரு மேற்கோளைப் பெறுங்கள்